ARE PATENTED / PATENT PENDING

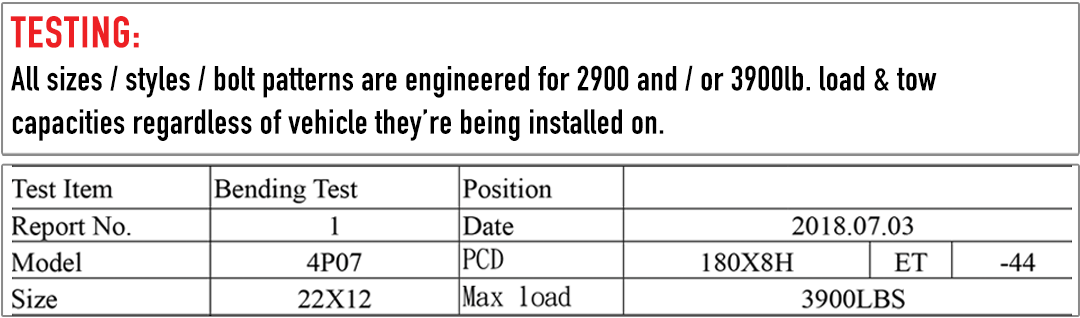

The 4PLAY® Gen2 Cast Series introduced industry changing designs engineered around HD load capacities and available in 5 styles, 3 sizes and multiple fitments.

4PG2 SERIES: STRENGTH & DURABILITY

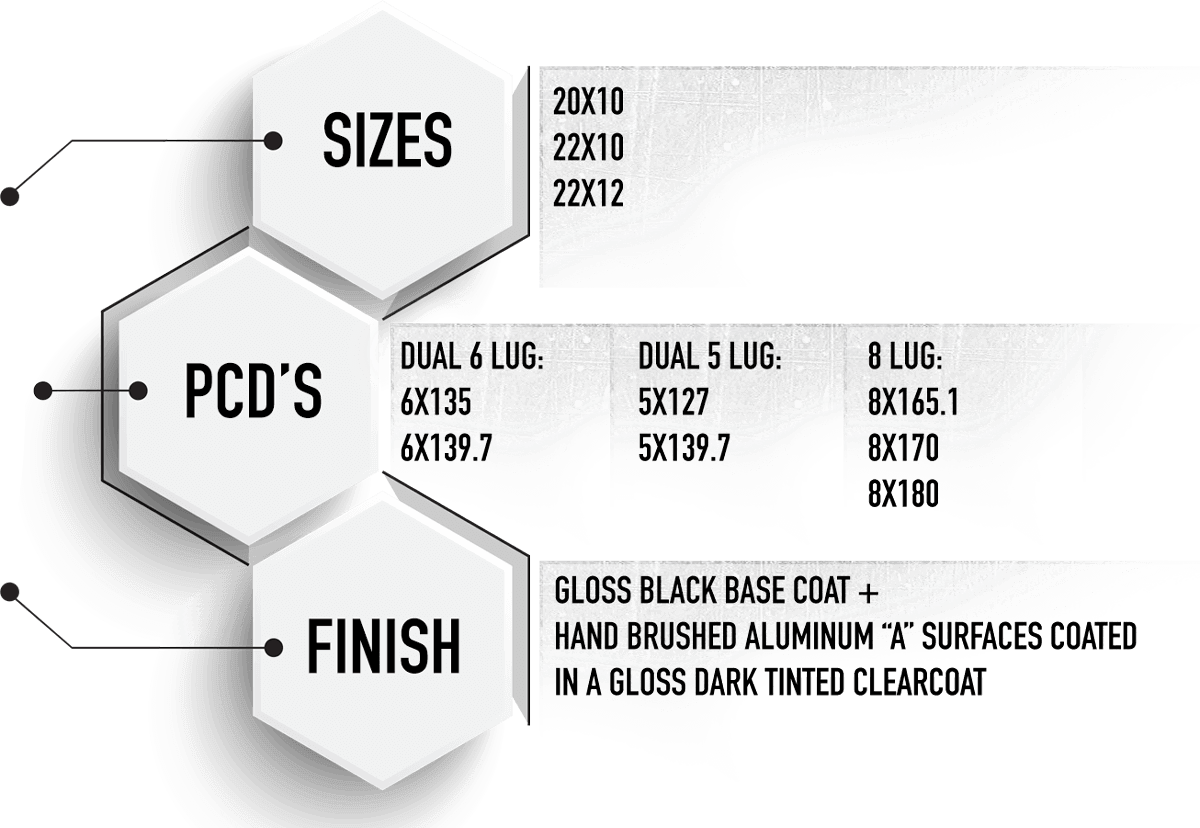

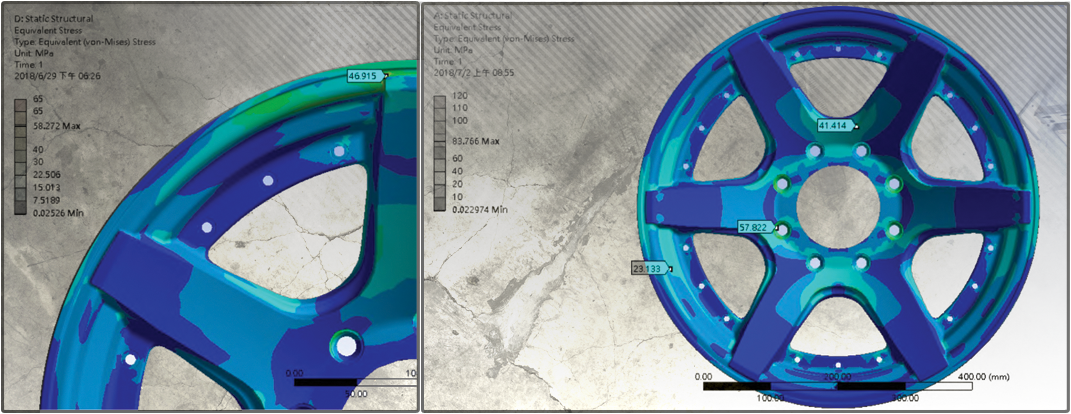

All of our wheels, regardless of the vehicles weight. load and tow capacity, are engineered around HD Truck / 3900 lb. per wheel load capacity meaning all of our wheels. in any size, bolt pattern or fitment are all designed, engineered and tested to easily sustain the highest level of vehicle load capacities, towing capacities and strength testing parameters.

TESTING CERTIFICATION & RUNOUT DOCUMENTATION:

All 4 PLAY wheel orders include an individually signed runout and test certification tag to ensure that all of our wheels are delivered with the highest possible level of quality control.

4PG2: TECHINCAL SPECS & FEATURES

MANUFACTURING PROCESS

4PLAY Wheels are manufactured by one of the leading OEM wheel manufacturers in the industry. We have long standing relationships with many manufacturers that we’ve been working with for over 20 years, and although we chose the highest priced manufacturer by far, we did so in order to create a truly better than OEM quality off road wheel that is not only safe & durable but also made using the highest quality materials and latest manufacturing processes.

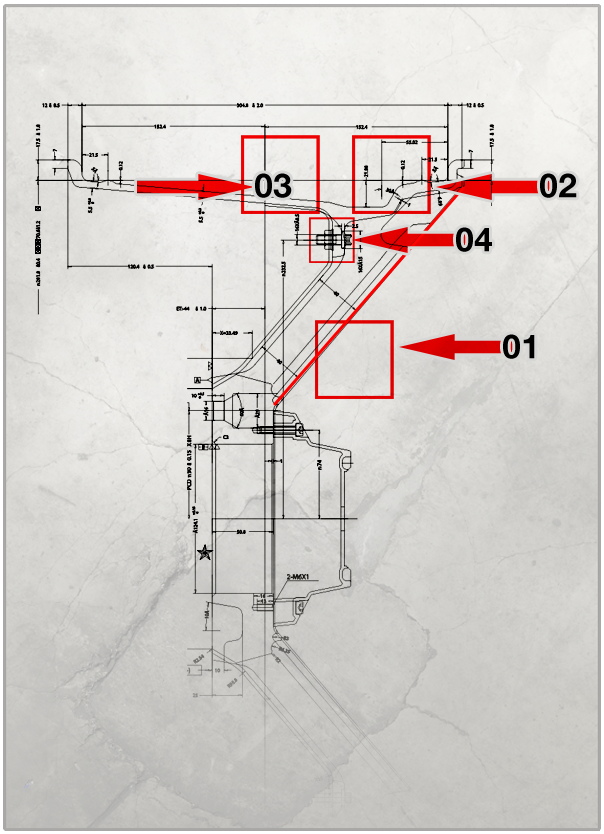

01. INCREDIBLY DEEP CONCAVE PROFILE

Rather than follow the trend, we prefer to set new ones. Almost all competing off road wheels are designed around the same flat profile with a deep. flat lip… Play wheels use technology and design inspired by trends seen mostly in the high end exotic automotive wheel segment. We’ve combined that cutting edge design and engineering technology with high strength cast wheel manufacturing and mold development to create an entirely new type of off road wheel that will set the trend for all off road wheels in the years to come in terms of both aesthetic style and design.

02. "STEP LIP" CONTOUR

Also previously seen primarily on forged multi piece race and exotic wheels, the STEP LIP contour provides added strength and bend resistance due to it’s “stepped” contour which is much stronger than any comparable size flat lip wheel on the market today. The step lip was originally designed specifically to decrease weight and increase strength on multi piece wheels. We’re proud to be the 1st to introduce this technology to the off road wheel market. Additionally, the combination of step lip contour with the deep concave profile as shown, is a patent pending design/engineering aspect that we have developed, hindering the ability of competing brands to copy the look and design of 4PLAY Wheels.

03. ANTI-WATER RETENTION

Another benefit of the step lip contour is the elimination of a common issue known as “water retention”, which is when water puddles inside the inner barrels “drop center” area on most wheels. This water retention can cause temporary vibration and safety issues in many cases. Our wheels do not have the typical “drop center” area on the inner barrel, which eliminates the possibility of any water from being trapped inside the retention area…Ever!

04. STAINLESS STEEL 2 PIECE HARDWARE

We’ve added a multi piece style “faux” assembly flange which provides additional strength and bend resistence as a result of the added ring of material around the inner diameter of the wheel. To make this strength/aesthetic feature look it’s best. we’ve engineered all of our wheels for use with a 2 piece, high quality stainless steel hex bolt with open end rear mounted nut

CERTIFICATION

All 4PLAY® wheel orders include an individually signed runout & test certification tag to ensure that all of our wheels are delivered with the highest possible level of quality.