Technical

Manufacturing process

4PLAY® Wheel utilizes only the most advanced OEM wheel manufacturing facilities in the industry. For over 20 years we’ve forged long standing, close business relationships with our partners around the globe. As a result, we’re able to produce aftermarket wheels built to the exacting and stringent standards required of OEM manufacturers while emphasizing design components that are usually only seen on custom aftermarket wheels. We’ve opted to use the highest cost manufacturing processes and factories as to guarantee the absolute best product available using the latest technology and processes.

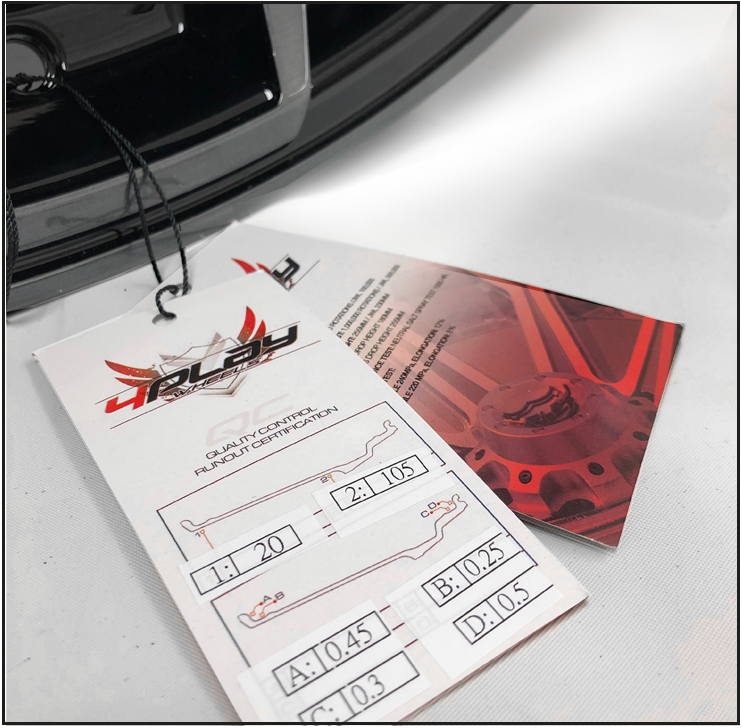

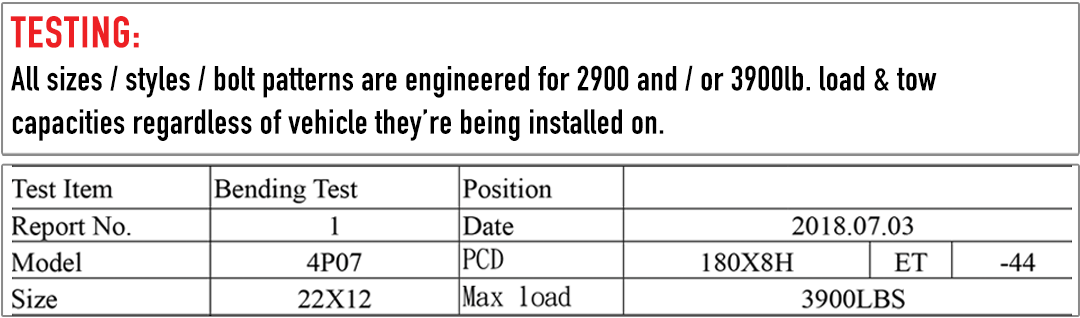

Lateral+Radial

Run out certification

4PLAY® Wheels is obsessed with providing the highest quality cast & forged wheels in the industry. Our OEM certified manufacturing facilities combine the rigorous testing requirements of factory production with the boutique finishing of a custom wheel facility. Our automated facility puts every wheel through multiple QC test, including Radial & Lateral run-out testing. We include individually signed runout test certification tags to ensure that our customers have confidence & trust in our products.

Hand brushed

finishing

Although we specialize in high volume wheel production, we haven’t forgotten about the details. Combining the rigorous testing requirements of OE wheel supply with the artisan techniques of custom wheel finishing, 4PLAY® Wheel’s signature finish set trends in the industry that are yet to be replicated. True, hand-brushed A-surfaces with a silky smooth, tinted clear-coating provides a unique finish that looks at home in dirt or the valet lot.

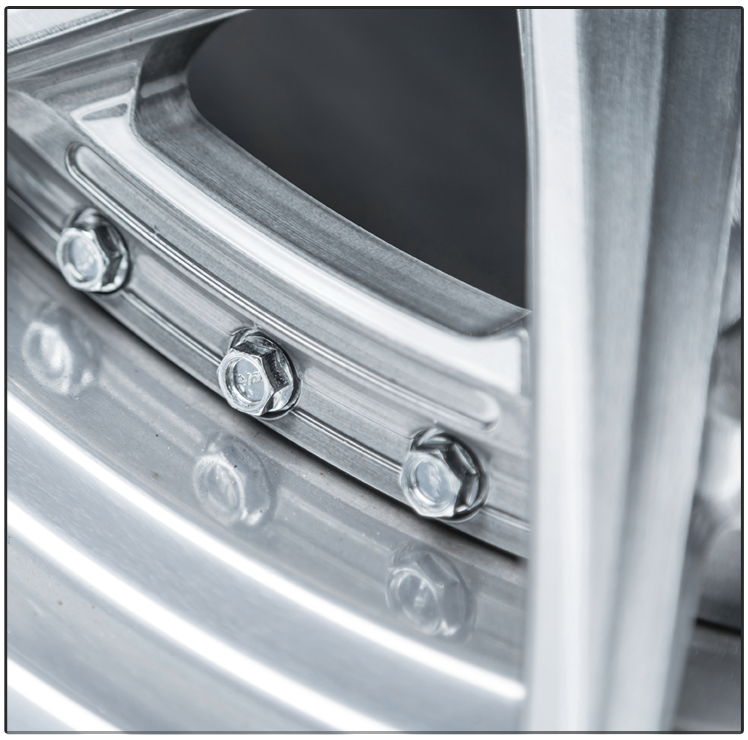

4Play stainless

hardware

They say the devil is in the details. We know our customers expect their vehicles, and their wheels, to take them where they need to go, regardless of the elements. That’s why 4PLAY® Wheels uses true stainless-steel through bolts. No more rusted rivets after 1 winter. Can the competition say the same?

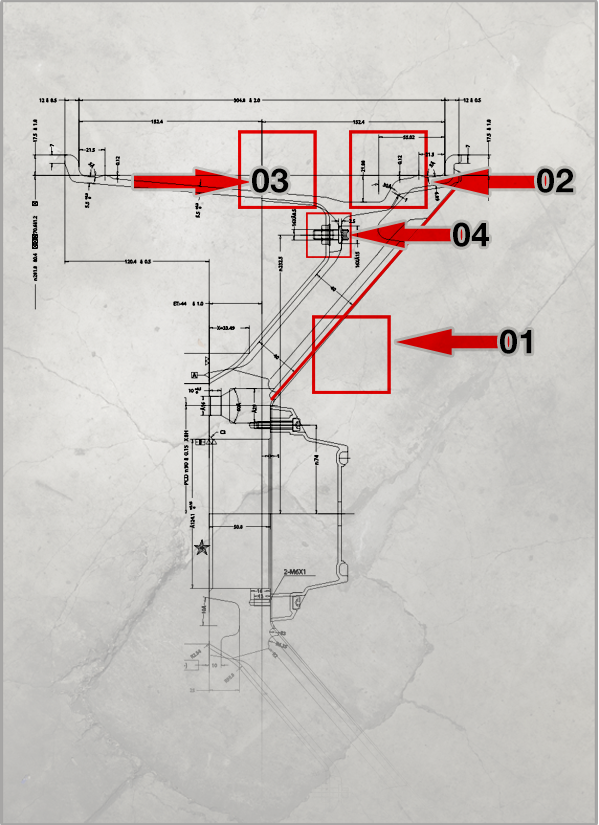

GEN2 GEN3 & FORGED SERIES DEEP CONCAVE PROFILES:

Rather than follow trends, 4PLAY® Wheels prefers to set them. The aftermarket industry is plagued with wheels from all different brands that offer the same old flat-face profile with a flat lip, and rivets drilled into a flat flange. 4PLAY® wheels use technology and design techniques inspired by products seen mostly in the high performance or exotic supercar market. We’ve combined that cutting edge design and engineering technology with high strength components to produce a concave truck & off-road profile that is instantly recognizable from any angle.

"STEP LIP" CONTOUR:

Further setting 4PLAY® Wheels ahead of the pack, our step-lip technology, derived from performance motorsports, provides added strength and rigidity. This manufacturing technique was originally designed to decrease weight while increasing strength on multi-piece wheels. We’re proud to be the 1st to introduce this technology to the off-road wheel market.

ANTI-WATER RETENTION:

Another benefit of the step-lip contour is the elimination of a common issue known as water-retention. When water puddles inside the wheel’s “drop center” it can cause temporary vibration and safety issues as well as finish corrosion concerns. Our wheels do not have the typical “drop center” area on the inner barrel, which eliminates the potential vibration issue and makes cleaning your wheels a breeze.

STAINLESS HARDWARE:

They say the devil is in the details. We know our customers expect their vehicles, and their wheels, to take them where they need to go, regardless of the elements. That’s why 4PLAY® Wheels uses true stainless-steel through bolts. No more rusted rivets after 1 winter. Can the competition say the same?

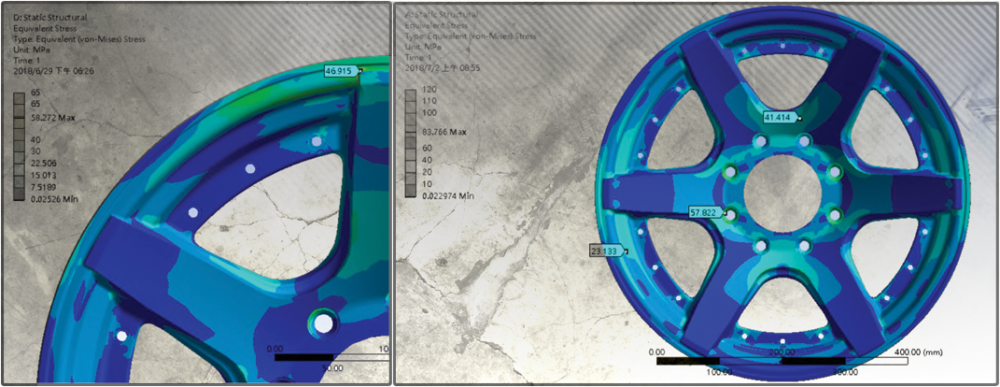

STRENGTH & DURABILITY TESTING All 4PLAY®

Wheels are engineered and tested to exceed the most current Truck and SUV load capacities. Meaning, all 4PLAY® 8 lug wheels are tested to a 3900 lb. rating per wheel and all 5 and 6 lug wheels are designed and tested to a 2900 lb. rating per wheel. We do this to ensure maximum strength and durability on all our wheel designs. Safety and product durability are paramount in our manufacturing procedures and one of our highest concerns. Everything we engineer/produce follows these rigorous guidelines, including Flow Formed and multipiece wheels.

CERTIFICATION

All 4PLAY® wheel orders include an individually signed runout & test certification tag to ensure that all of our wheels are delivered with the highest possible level of quality.

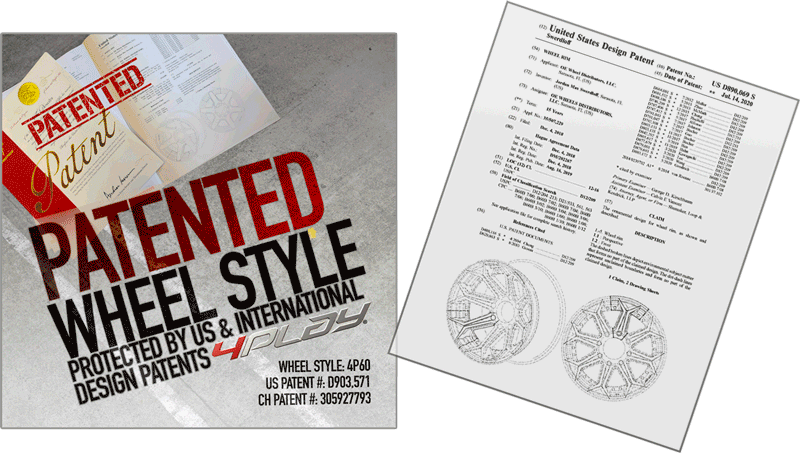

PATENTED DESIGNS:

In an industry dominated by few, 4PLAY Wheels® is willing and able to take the appropriate actions necessary to ensure the protection of the brand and wheel styles that we have worked tirelessly to create with the faith and support of every customer that we have had the honor and privilege of supplying. All of our wheel styles are patented or in patent pending stage and we are fully committed to defend our intellectual property against anyone who attempts to copy our styles, or any aspects of our styles.

Damage proof packaging

Understanding that the customer’s experience is as important as the product, we make sure your wheels arrive trouble-free. Each wheel is packaged with excessive safety materials such as corner protectors, top and bottom reinforcements, and high-quality scratch resistant 4PLAY® Wheels branded bonnets to ensure a perfect product arrives every time.

In house mounting & balancing

OE Wheels® / 4PLAY® Wheels facilities are fully equipped with the latest tire mounting and balancing equipment. We have access to all major tire distributors who can provide us with most major brands, treads, and sizes. All our customer orders can be upgraded to a Wheel & Tire package which includes Road Force® Balancing, palletized shipping, and all necessary TPMS sensors and installation hardware needed for a trouble-free installation.

Understanding that the customer’s experience is as important as the product, we make sure your wheels arrive trouble-free. Each wheel is packaged with excessive safety materials such as corner protectors, top and bottom reinforcements, and high-quality scratch resistant 4PLAY® Wheels branded bonnets to ensure a perfect product arrives every time.

OE Wheels® / 4PLAY® Wheels facilities are fully equipped with the latest tire mounting and balancing equipment. We have access to all major tire distributors who can provide us with most major brands, treads, and sizes. All our customer orders can be upgraded to a Wheel & Tire package which includes Road Force® Balancing, palletized shipping, and all necessary TPMS sensors and installation hardware needed for a trouble-free installation.